Wastewater Lagoon Basics

Wastewater lagoons are designed and built in various shapes and sizes depending on land availability and the amount and type of wastewater being treated. While there are many different nomenclatures and designations, the most accurate way of defining wastewater lagoons is by identifying the method of introducing of oxygen into the treatment process. While there are several important factors required for the successful operation of a wastewater lagoon, the most important element involves the provision of oxygen in sufficient amounts and at the correct location throughout the treatment process. A summary of the different methods used to inject oxygen into the treatment process is as follows:

Natural Aeration

A wastewater lagoon that depends on natural weather conditions and does not include a specific methodology for adding oxygen into the treatment process is identified as a facultative, stabilization or maturation pond. These ponds do not depend on mechanical or biological processes to add oxygen to the system. The small amount of oxygen that naturally occurs in these systems is located within the upper two inches of the water surface and provides little benefit towards establishing effective aerobic digestion. As a result, these lagoons require longer Hydraulic Retention Time (HRT) and substantially more land area. They generally produce more odor and sludge and are limited in use to smaller communities in rural areas.

Mechanical Aeration

Mechanically aerated wastewater lagoons provide better treatment results, but are more expensive to install and operate. Oxygen is introduced into the wastewater lagoon mechanically though different applications such as surface aerators, small and large bubble diffusers and rotating wheels. The number of aeration components and the placing of the components within the wastewater lagoon is critical to providing adequate amounts of oxygen needed for the treatment process.

There are major weaknesses in the utilization of mechanical aerators as part of the treatment process. Mechanical aerators break down frequently and are difficult to retrieve and repair. They use large amounts of energy, and they can disrupt essential lagoon flow patterns. The air we breathe, which contains only 20% oxygen, is the same air injected into wastewater lagoons by aerators. Additionally, this limited amount of oxygen is only assimilated by water in the lagoon at a rate of 5% to 10%. These factors dramatically reduce the amount of oxygen which is available for healthy, aerobic activity within a lagoon.

Biological Aeration Through Photosynthesis

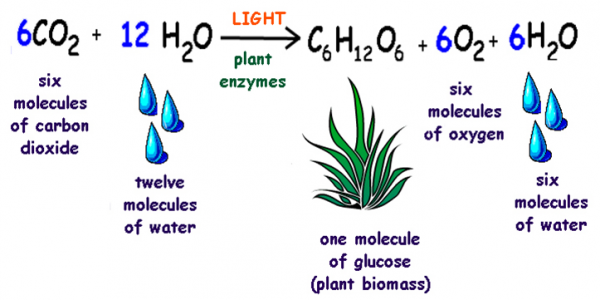

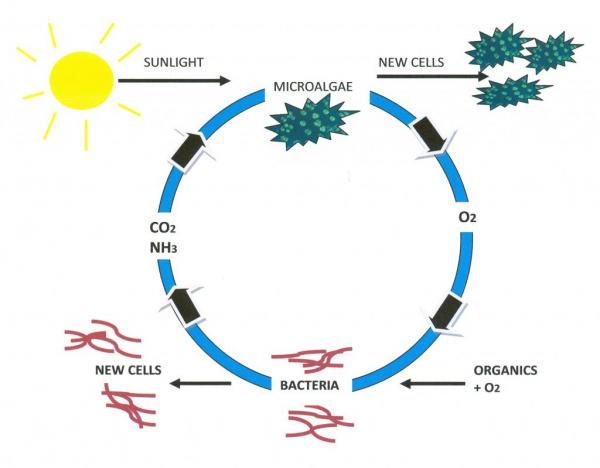

When microscopic, multi-species, single cell algae are exposed to sunlight in a wastewater lagoon, a uniform 18" to 24" layer of pure oxygen is developed and becomes available immediately and directly to the aerobic bacteria which are responsible for the digestion of organic solids. The bacteria release carbon dioxide (CO2) as part of their digestive process, which becomes a carbon source for the microalgae which, in turn, respond by creating more pure oxygen for the bacteria. Utilizing photosynthesis, the microalgae and microbial bacteria create a symbiotic relationship which maximizes the breakdown of organic solids within the treatment process. Table 1, “Summary of Oxygen Generation Rates”, compares the amount of oxygen produced by various aeration methods.

Surface Mechanical Aerators (Blowers)

- High initial costs

- High electrical power consumption

- Continual maintenance

- Limited adjustment flexibility for lagoon fluctuations

- Limited oxygen transfer efficiency

Biological Oxygen Generators (Microalgae)

- Low initial cost

- Low power requirement (solar)

- Pure oxygen generation

- Variable oxygen production depending on change of influent characteristics

- Laminar mixing provided by fine bubble diffusers